Manual handling for disability support workers involves safely moving and supporting individuals with disabilities. It promotes independence, prevents injuries, and ensures dignity, making it a foundational skill.

1.1 Overview of Manual Handling

Manual handling refers to the physical movement or support of clients, including lifting, lowering, carrying, pushing, or pulling. It is a critical skill for disability support workers, ensuring clients’ safety and dignity while minimizing injury risks. Proper techniques involve using body mechanics, assistive devices, and safe lifting practices. The goal is to maintain client independence and comfort while protecting both the worker and the individual from harm. Effective manual handling requires training, awareness of environmental factors, and adherence to safety guidelines to prevent musculoskeletal disorders and other injuries. It is a cornerstone of disability support care, emphasizing respect and professionalism in all interactions.

1.2 Importance of Safe Manual Handling

Safe manual handling is essential to protect both disability support workers and clients from injuries. Improper techniques can lead to musculoskeletal disorders, strains, and long-term health issues for workers, while clients may suffer discomfort or harm. Safe practices ensure clients are handled with dignity and respect, maintaining their independence and well-being. Employers reduce workplace injuries, lower absenteeism, and avoid legal liabilities by promoting safe manual handling. Proper training and adherence to guidelines create a safer, more efficient care environment, benefiting everyone involved. Prioritizing safety fosters trust and professionalism in disability support services.

Legal and Regulatory Frameworks

Legal frameworks ensure compliance with safety standards, protecting workers and clients. Employers must adhere to occupational health laws, while workers follow safe practices to minimize risks and injuries.

2.1 Relevant Laws and Regulations

The primary legislation governing manual handling in disability support work is the Work Health and Safety Act 2011 (WHS Act). This act requires employers to ensure a safe work environment, including proper manual handling practices. Additionally, the Disability Standards for Accessible Public Transport 2002 and the National Disability Insurance Scheme (NDIS) Quality and Safeguards Commission regulate safe client handling. Specific regulations, such as the Manual Handling Regulations under the WHS Act, outline requirements for risk assessments and training. State-based occupational health and safety acts also enforce compliance, ensuring workers and clients are protected.

2.2 Employer Responsibilities

Employers in disability support services must provide a safe work environment by identifying and managing manual handling risks. They are responsible for conducting regular risk assessments and implementing control measures. Employers must provide appropriate training and ensure workers are competent in safe manual handling techniques. They must also supply suitable equipment and resources to minimize manual handling risks. Employers are obligated to monitor and supervise the implementation of safe practices and review these measures regularly. Additionally, they must ensure that all policies and procedures align with relevant laws and standards, fostering a culture of safety and accountability within the workplace.

2.3 Worker Rights and Duties

Disability support workers have the right to a safe working environment and must be provided with proper training and equipment. They are entitled to report hazards without retaliation and refuse tasks that pose unacceptable risks. Workers must adhere to safe manual handling practices, use provided equipment correctly, and follow workplace policies. They are responsible for actively participating in training, informing employers of potential risks, and maintaining open communication with clients and colleagues. Additionally, workers must respect clients’ autonomy while ensuring their safety during manual handling tasks. Fulfilling these duties ensures both worker and client well-being and compliance with legal requirements.

Hazards and Risks Associated with Manual Handling

Manual handling in disability support involves risks like physical strain, awkward postures, and client-related factors, requiring careful assessment to prevent injuries and ensure safe care delivery.

3.1 Physical Hazards

Physical hazards in manual handling for disability support workers include awkward postures, repetitive movements, and forceful exertions, which can strain muscles and joints. These hazards often arise from lifting, transferring, or repositioning clients, especially when improper techniques are used. Prolonged or frequent manual handling can lead to injuries such as sprains, strains, or chronic musculoskeletal disorders. Additionally, the physical demands of supporting clients with mobility impairments can exacerbate existing health conditions. Identifying these risks is crucial to implementing preventive measures and ensuring a safer working environment for both workers and clients.

3.2 Environmental Factors

Environmental factors significantly impact manual handling safety for disability support workers. Cluttered workspaces, uneven surfaces, and poor lighting can increase the risk of accidents. Narrow pathways or doorways may hinder safe client transfers, while slippery floors can lead to falls. The layout of client rooms, such as the placement of beds or bathrooms, can also affect how tasks are performed. Additionally, extreme temperatures or inadequate ventilation may contribute to worker fatigue. Addressing these environmental challenges is essential to minimize hazards and ensure a safer working environment for both workers and clients. Proper workplace design and maintenance can help reduce these risks effectively.

3.3 Client-Related Risks

Client-related risks in manual handling for disability support workers arise from specific client characteristics. These include the client’s physical condition, such as being overweight or having fragile bones, which can complicate lifting and transferring. Limited mobility or dependence on the worker increases handling difficulty. Unpredictable movements or spasms in clients with neurological conditions can pose challenges. Behavioral factors, like resistance or anxiety due to cognitive impairments, may lead to unsafe situations. Size discrepancies between the client and worker can result in improper lifting techniques. Communication barriers may prevent clients from expressing discomfort, while specific postural needs or medical histories, such as past injuries, require tailored handling approaches. Balancing client autonomy with safety is crucial, ensuring involvement while maintaining a safe environment. Effective strategies must address these risks to protect both clients and workers, fostering a safe and respectful care setting. Proper training and client-specific planning are essential to mitigate these client-related risks effectively.

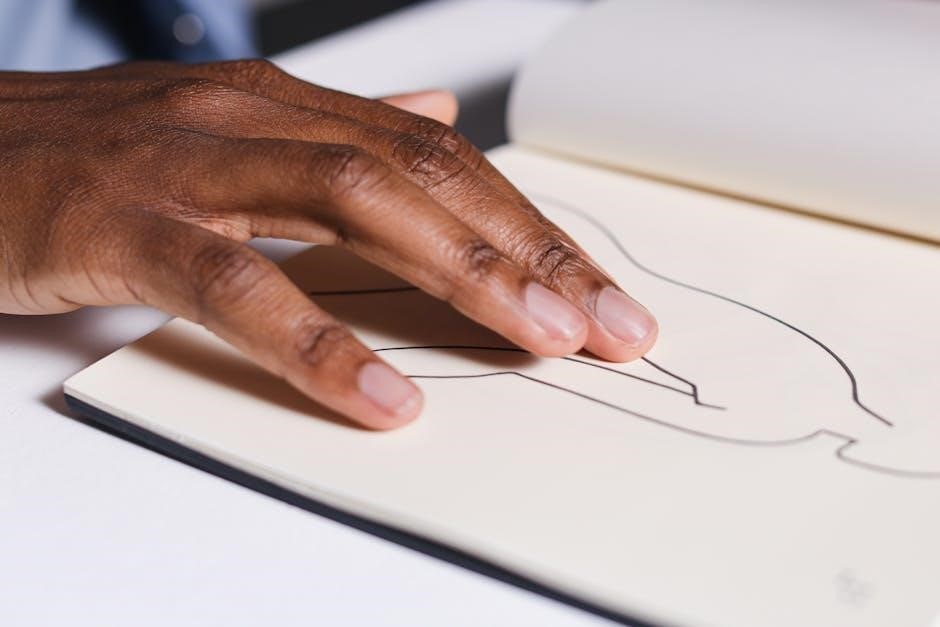

Safe Manual Handling Techniques

Safe manual handling techniques involve proper posture, effective body mechanics, and the use of assistive devices to minimize injury risks, ensuring safe client handling and transfer processes.

4.1 General Principles

General principles of manual handling emphasize a proactive approach to minimizing risks. Proper planning and assessment of tasks are crucial to ensure safety. Maintaining good posture and balance reduces strain, while using assistive devices can prevent overexertion. Prioritizing client-centered care ensures techniques align with individual needs. Training in these principles helps workers develop muscle memory for safe practices, reducing the likelihood of injuries. Regular review and updating of techniques are essential to adapt to changing client requirements and workplace conditions.

4.2 Proper Posture and Body Mechanics

Proper posture and body mechanics are foundational to safe manual handling. Maintaining a neutral spine alignment ensures even weight distribution and minimizes strain. When lifting or moving clients, bending at the knees rather than the waist reduces lower back stress. Keeping the client or object close to the body lowers the risk of injury. Engaging core muscles provides stability, while avoiding twisting movements protects the spine. Proper foot placement and balance further enhance control. Consistently applying these principles reduces fatigue and injury risks, promoting effective and safe manual handling practices in disability support settings.

4.3 Lifting Techniques

Effective lifting techniques are essential for minimizing injuries and ensuring safe manual handling. The squatting method, where knees are bent and weight is distributed evenly, is ideal for lifting clients or objects. Keeping the load close to the body maintains balance and reduces strain. A firm grip and secure hold prevent slipping, while lifting smoothly avoids jerking movements. Planning the lift, including the path and destination, enhances safety. Using assistive devices when necessary further reduces physical demands. Encouraging clients to assist where possible promotes independence and shared responsibility. These techniques minimize strain and ensure safe, efficient lifting in disability support settings.

4.4 Transferring and Positioning

Safe transferring and positioning are critical to prevent injuries and ensure client comfort. Techniques include using slide sheets, transfer belts, and pivot transfers to maintain control and reduce strain. Communication is key; clear instructions and consent from the client are essential. Assessing the client’s strength, mobility, and medical conditions helps tailor the transfer. Using assistive devices like hoists or standing aids can minimize manual effort. Always maintain a stable base of support and keep the client close to your body. Posture should be upright with slight bending at the hips and knees. Documentation of transfer plans ensures consistency and safety across care settings.

4.5 Use of Equipment and Assistive Devices

The use of equipment and assistive devices is essential for safe and effective manual handling. Tools like hoists, slide sheets, and transfer belts can significantly reduce physical strain and prevent injuries. Hoists, for example, allow for the safe lifting and transferring of clients with minimal manual effort. Slide sheets facilitate smooth movements between surfaces, minimizing friction and discomfort. Transfer belts provide additional control during transfers. Assistive devices such as standing aids or grab bars can also support clients during repositioning. Proper training in the selection, use, and maintenance of these devices is crucial to ensure safety and effectiveness. Always match the device to the client’s specific needs and abilities.

Training and Education

Effective training and education are critical for developing safe manual handling skills. Programs should cover theoretical knowledge, practical demonstrations, and real-life scenarios to ensure competence and confidence.

5.1 Manual Handling Training Programs

Manual handling training programs are structured courses designed to equip disability support workers with the necessary skills and knowledge to perform tasks safely. These programs typically include both theoretical and practical components, ensuring participants understand the principles of safe manual handling. Key elements covered include risk assessment, proper lifting techniques, and the use of assistive devices. Hands-on practice allows workers to apply learned techniques in real-life scenarios. The goal is to reduce the risk of injury to both workers and clients while promoting a culture of safety and legal compliance. Regular updates to training ensure adherence to best practices and industry standards.

5.2 Components of Effective Training

Effective manual handling training incorporates clear learning objectives, interactive delivery methods, and practical exercises. It should include demonstrations, case studies, and group discussions to engage participants. Practical sessions allow workers to practice techniques under supervision, ensuring proper execution. Expert trainers provide immediate feedback, addressing incorrect practices and reinforcing safe methods. Training materials, such as manuals and videos, support learning. Assessment of understanding through quizzes or practical tests ensures competency. Regular refresher courses and updates keep skills current. Tailoring content to specific workplace scenarios enhances relevance and application. A well-structured program ensures workers are confident and competent in applying manual handling techniques safely and effectively in their roles.

5.3 Role of Classroom and Practical Training

Classroom training provides foundational knowledge on manual handling principles, risks, and legal requirements, ensuring a theoretical understanding. Practical training reinforces this by allowing workers to apply techniques in real-life scenarios. Hands-on sessions help develop muscle memory and confidence in performing tasks safely. Simulated exercises mimic workplace challenges, enabling workers to practice handling diverse client needs. Feedback from instructors during practical sessions ensures proper technique and addresses errors. This blended approach enhances learning retention, as workers can immediately apply what they’ve learned. Combining classroom and practical training ensures disability support workers are well-prepared to manage manual handling tasks effectively and safely in their daily roles.

Risk Assessment and Management

Risk assessment and management are crucial for identifying and mitigating manual handling hazards. They ensure safe practices, protecting both clients and workers from potential injuries and harm effectively.

6.1 Conducting a Risk Assessment

Conducting a risk assessment involves systematically identifying and evaluating manual handling hazards. Disability support workers must observe tasks, consult with clients, and use checklists to identify potential risks. The assessment should consider the client’s abilities, the environment, and the task’s demands. It is essential to prioritize client-centered approaches, ensuring their autonomy and specific needs are respected. Legal compliance and workplace policies must also guide the process. By prioritizing high-risk tasks and documenting findings, workers can develop targeted strategies to minimize harm. Regular reviews of risk assessments ensure ongoing safety and adapt to changing client or environmental conditions.

6.2 Identifying High-Risk Tasks

Identifying high-risk manual handling tasks is crucial for minimizing injuries. These tasks often involve heavy lifting, awkward postures, or repetitive movements. For disability support workers, high-risk tasks may include transferring clients with limited mobility, lifting clients from the floor, or assisting with toileting. Assessing the weight of the client, the frequency of the task, and the environment can help identify risks. Observing the task, consulting with clients, and using risk assessment tools are effective methods. Prioritizing tasks based on their risk level ensures targeted interventions. High-risk tasks often require specialized equipment or additional support to reduce the likelihood of injury to both workers and clients.

6.3 Developing a Risk Management Plan

A risk management plan is essential for addressing manual handling risks. It involves identifying hazards, assessing their likelihood and impact, and implementing controls. The plan should outline strategies to eliminate or reduce risks, such as using assistive devices or modifying tasks. Monitoring and reviewing the plan ensures ongoing effectiveness. Collaboration with clients, supervisors, and healthcare professionals is key to tailoring the plan to individual needs. Documentation of the plan and its outcomes promotes accountability and continuous improvement. A well-structured risk management plan not only protects workers but also enhances client safety and care quality, making it a cornerstone of safe manual handling practices in disability support settings.

Ergonomic Considerations

Ergonomic considerations in manual handling focus on optimizing workplace environments and tasks to reduce strain and prevent injuries. Proper posture, equipment, and space alignment are prioritized to enhance safety and efficiency for disability support workers.

7.1 Workplace Setup and Layout

A well-designed workplace setup and layout are critical for safe manual handling in disability support. Ensure work areas are uncluttered, with adequate space for movement and clear pathways. Install height-adjustable equipment, such as beds or tables, to minimize bending and reaching. Position frequently used items within easy reach to reduce stretching. Use non-slip flooring and proper lighting to enhance visibility and safety. Ergonomic chairs and assistive devices should be available to support workers during tasks. Regularly assess the environment to identify and address potential hazards, ensuring a safe and efficient workspace for both workers and clients.

7.2 Use of Assistive Technology

Assistive technology plays a vital role in reducing manual handling risks for disability support workers. Devices such as hoists, sliding boards, and transfer belts can significantly minimize physical strain. Electric beds and adjustable bathing chairs also contribute to safer client transfers. These tools enhance client mobility while protecting workers from injury. Proper training on the use of assistive technology is essential to maximize its benefits. By incorporating these devices, workers can promote client dignity and independence. Regular maintenance of equipment ensures reliability and safety. Investing in assistive technology not only improves workplace safety but also enhances the overall quality of care provided to clients.

7.3 Personal Protective Equipment

Personal Protective Equipment (PPE) is essential for disability support workers to minimize injuries during manual handling tasks. Gloves protect hands from cuts and abrasions, while back supports help maintain proper posture and reduce strain. Non-slip footwear prevents falls, enhancing stability during client transfers. PPE should be worn according to workplace policies and task requirements. Regular inspection and maintenance of PPE ensure its effectiveness. Proper training on PPE use is crucial to maximize protection. By prioritizing PPE, workers can safeguard their health while providing safe and dignified care to clients. This proactive approach reduces workplace injuries and promotes a safer environment for everyone involved.

Client-Centered Manual Handling

Client-centered manual handling prioritizes the client’s autonomy, comfort, and dignity, ensuring their unique needs and preferences guide all support actions during transfers and care tasks.

8.1 Understanding Client Needs

Understanding client needs is crucial in manual handling for disability support workers. Each client has unique requirements based on their disability, medical conditions, and personal preferences. Conducting thorough assessments and developing individualized care plans ensure that support is tailored to their specific needs. This includes considering their physical capabilities, mobility levels, and any assistive devices they use. Effective communication and active listening are essential to identify their preferences and ensure their comfort and dignity during manual handling tasks. Recognizing these factors allows workers to provide safe, respectful, and client-centered care, minimizing risks and promoting independence.

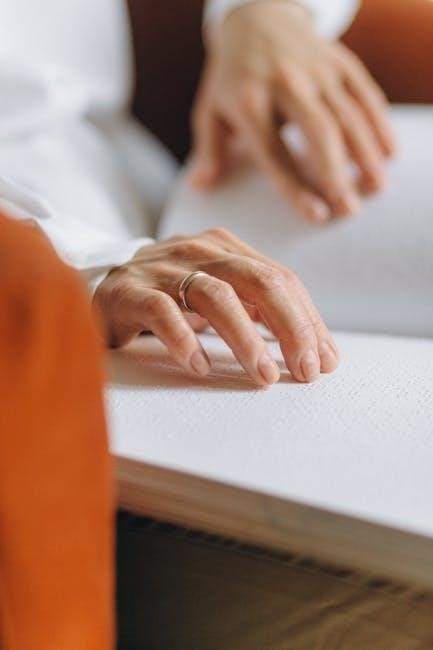

8.2 Communication Strategies

Effective communication is vital for safe and respectful manual handling in disability support. Clear, simple, and consistent language ensures understanding between workers and clients. Active listening and non-verbal cues, such as gestures and facial expressions, enhance communication, especially for clients with hearing or speech impairments. Involving clients in decision-making fosters trust and empowerment, allowing them to express preferences or concerns. Providing feedback during tasks ensures clarity and adaptability. For clients with communication barriers, tools like visual aids or communication boards can be used. Regular training in communication techniques helps workers address diverse needs, ensuring dignity and safety are prioritized in every interaction.

8.3 Involving Clients in the Process

Involving clients in manual handling ensures their autonomy and dignity are respected. Encouraging clients to participate in planning and decision-making fosters trust and cooperation. Providing clear information about the process helps clients understand their role and expectations. Actively seeking their feedback and preferences ensures personalized and safer handling practices. Demonstrating techniques and allowing clients to guide the process can enhance their comfort and confidence. Supporting clients to maintain as much independence as possible promotes empowerment and reduces reliance on caregivers. Regularly reviewing and adjusting the approach based on client input ensures ongoing safety and satisfaction. Client involvement is essential for effective and person-centered care.

Injury Prevention and Management

Injury prevention and management are critical for ensuring client and worker safety. Proactive strategies, proper techniques, and prompt incident response are essential for minimizing harm and fostering recovery.

9.1 Strategies for Preventing Injuries

Effective injury prevention requires a combination of proper training, equipment use, and workplace practices. Disability support workers should undergo regular manual handling training to learn safe techniques. Conducting thorough client assessments ensures personalized care plans that minimize risks. Using assistive devices, such as hoists or slide sheets, reduces physical strain. Encouraging open communication between clients and workers helps identify potential hazards. Maintaining a safe work environment, free from obstacles and with proper lighting, further reduces injury risks. Regular breaks during tasks and promoting client independence can also prevent fatigue-related injuries. Monitoring and reviewing these strategies ensures ongoing safety and adaptability to client needs.

9.2 Reporting and Managing Injuries

Reporting and managing injuries is crucial for maintaining workplace safety and ensuring proper care. All incidents must be documented promptly using incident reports or first aid records. Employers should investigate injuries to identify root causes and prevent recurrence. Immediate care, such as first aid, should be provided, and medical attention sought if necessary. Workers must report injuries to their supervisor and complete any required forms. Employers should also monitor recovery progress and facilitate return-to-work plans. Open communication between workers, employers, and healthcare providers ensures effective management. Proper documentation and follow-up help create a safer environment and reduce future risks for disability support workers.

9.3 Rehabilitation and Return to Work

Rehabilitation and return-to-work programs are essential for supporting workers recovering from manual handling injuries. These programs aim to restore physical and functional abilities through tailored exercises, therapy, and medical oversight. Employers should collaborate with healthcare providers to create a gradual return-to-work plan, ensuring tasks are modified to accommodate the worker’s capabilities. Open communication between the worker, employer, and medical team is vital to monitor progress and adjust plans as needed. Providing access to counseling or ergonomic assessments can further aid recovery. The goal is to safely reintegrate workers into their roles while minimizing the risk of re-injury and promoting long-term well-being in the disability support workplace.

Effective manual handling practices are crucial for ensuring both client well-being and worker safety. By prioritizing proper techniques, risk assessment, and ongoing education, disability support workers can minimize injuries and provide high-quality care while maintaining their own health and longevity in the profession.

10.1 Summary of Key Points

Manual handling in disability support requires a holistic approach, combining safe techniques, legal compliance, and client-centered care. Understanding physical hazards, environmental factors, and client-specific risks is essential. Employers must provide proper training and equipment, while workers should adhere to safe practices and report incidents promptly. Effective risk assessments and ergonomic workplace setups minimize injuries. Communication and client involvement ensure dignity and safety during handling. Regular training and the use of assistive devices are vital for maintaining worker well-being and delivering quality care. By prioritizing these elements, disability support workers can create a safer, more efficient, and respectful care environment for all parties involved.

10.2 The Future of Manual Handling in Disability Support

The future of manual handling in disability support lies in advancing technology and personalized care approaches. Innovations like robotic assistive devices and wearable exoskeletons are expected to reduce physical strain and enhance safety. Increased focus on client-centered practices will ensure dignity and autonomy, while data-driven assessments will improve risk management. Virtual reality training programs may become standard, offering immersive learning experiences. Collaboration between healthcare, technology, and disability sectors will drive these advancements. By embracing these developments, the industry can create a safer, more efficient, and client-focused manual handling environment, ultimately improving outcomes for both workers and clients.